contributed by Claudia Lezell, SSI, CTC, RFI, SCI, CWFI, ASID* [instructor, The Flooring Technology Institute / interior designer / industry overachiever]

After more than 20 years of involvement in the design, build, concrete, floor covering, and inspection industry, and now as a technical trainer, I am impressed with how these  industries have evolved in a relatively short period of time. As industry professionals, we owe it to our clients and consumers to stop for a moment to review the evolutionary process, evaluate how these changes have affected the flooring industry, and identify the new challenges that we face going forward.

industries have evolved in a relatively short period of time. As industry professionals, we owe it to our clients and consumers to stop for a moment to review the evolutionary process, evaluate how these changes have affected the flooring industry, and identify the new challenges that we face going forward.

High productivity in construction and building has had a positive effect on our economy. However, there are negatives associated with this boom, including shortages in concrete and building supplies, construction specifications too broadly written and left open to interpretation, and job delays. In addition, we have seen an increasing trend toward poor workmanship, such as installation shortcuts taken in order to quickly complete a project.

These construction problems are compounded by the fluctuating weather patterns in recent years. Unpredictable weather can cause challenges due to extreme temperature swings, excessive flooding, and job delays. Mother Nature’s fickleness can result in product failure, moisture intrusion, indoor air quality concerns, such as mold, and the potential for poor workmanship. Fortunately, along with these demands have come some solutions.

Evolution In Materials And Installation

As the environment has demanded more of the building industry, we have seen advancements in several areas. Concrete technology has grown over the years to include an increased selection of admixtures, such as pozzolana, accelerators, retarders, and high-range water reducers commonly called super plastizers. These chemicals can alter the time it takes for the concrete to set by shortening and lengthening that time depending on the need. We can also make more durable concrete and reduce the amount of water required to hydrate the mixture.

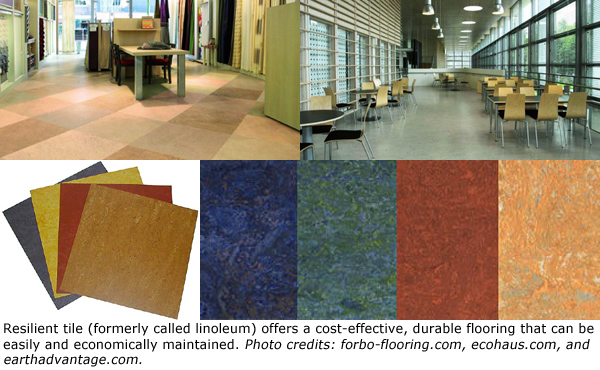

Concrete technology has been moving rapidly forward, and the technology of floor covering has made similar advancements. With resilient products, less permeability has led to improved cut and surface quality, edge tile formats with a broader selection of sizes and shapes, more durable floor finish and sealer formulations, and dry buff technology.

We have seen breakthroughs in the science of adhesives, membranes, and underlayments, along with increases in maintenance products and floor-covering materials. Overall, both installation methods and covering materials have seen steady improvements in strength, flexibility, variety, and versatility.

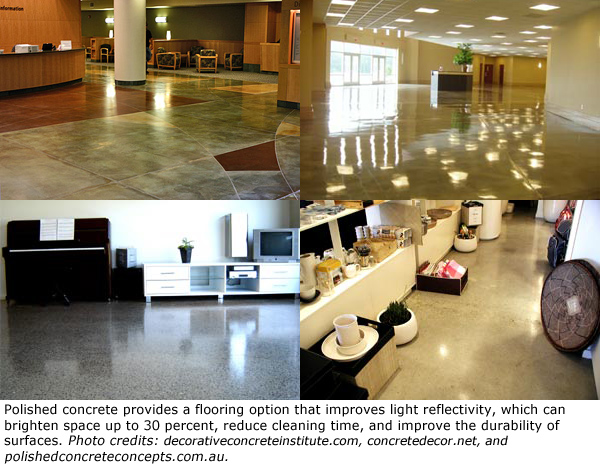

The versatility is also prevalent in the types of raw materials that are becoming more frequently used in the construction industry. Designers and technicians alike have access to a wide range of choices today, including unique and exotic species of wood from around the world, and a variety of flooring mediums that include a multitude of textures from specialty ceramics and glass to stone and stained concrete.

New Challenges

We would be remiss in the discussion of these new advancements if we did not acknowledge that the progress is accompanied by new challenges. In fact, we often encounter restrictions or even necessary accommodations when we incorporate the new materials. Although aesthetically pleasing, we must not forget that these exotic raw materials can carry with them idiosyncratic sensitivities to moisture, alkali, and / or dimensional growth factors. Unfortunately, if untrained labor sets these materials in an unacclimatized environment with moisture and alkaline-related conditions, a significant and costly failure is almost inevitable.

Certain environmental restrictions, such as the elimination of asbestos and chlorinated solvents, have caused major adjustments to occur in the way products are manufactured, disposed, installed, and maintained. This adds to the long list of necessary adjustments to how materials are manufactured, specified, handled, installed, and maintained in order to avoid serious floor covering failures. The necessary response to particular restrictions, such as stringent regulations on emissions and the release of kiln gases into the atmosphere, has led to changes in the composition of cement. This in turn affects the properties of concrete and the control of alkali.

Although there have been some improvements in the options available for concrete mix design and performance, we find new challenges in prescription and performance specification writing. The current recommendation in the ACI 302.R-04 Guide for Concrete Floor and Slab Construction as to where (or even if) to place the vapor retarder / barrier may not agree with some current philosophies of placement and vapor / barrier thickness. Despite the potential for improved efficiency in the installation of concrete that results from the use of curing compounds over a wet cover cure, those compounds prevent adhesion of most floor covering products. Ultimately, the time savings at the concrete stage needs to be weighed against the additional cost that could be incurred while removing such compounds to prep the concrete for floor covering.

In the same vein, there is confusion regarding testing standards. The method used to test concrete for moisture has come under great scrutiny, including the recent publication of two ASTM standards for testing the relative humidity in and on concrete versus the use of calcium chloride to obtain moisture vapor emission rate. With so many vital decisions to be made regarding concrete specification and a successful floor covering installation, it seems that with every answer follows yet another question.

Appropriate Actions

Our rallying cry has to be, “Out with the old and in with the new!” We have no choice. Old habits will have to die. The changes occurring within the CSI Specification Divisions, LEED, ASTM, ANSI, and the various changes with floor coverings and other materials are inevitable evolutionary steps. We cannot fight progress. However, we can respond by being proactive professionals and involving ourselves in this evolutionary process.

Now, more than ever, we must remain ahead of this advancement curve and stay current through continued education. We have to press for more detailed and appropriate specification and industry standards. Most importantly, we have to keep the lines of communication open between the various members of the design team to ensure that throughout the building process we stage jobs appropriately, test for moisture correctly, and condition the building envelope sufficiently. As always, the professional’s ultimate goal is to ensure a quality end product for our consumers.

Note: Excluding the photos, this article first appeared in the Nov/Dec 2005 issue of Texas Architect magazine. Claudia Lezell owns Inspections Too, Inc., a floor covering inspections business, has served as past co-chair of the NWFA Certification Committee, and spearheaded the Hard Surface Floor Covering Inspector Certification Programs for The Institute of Inspection, Cleaning and Restoration Certification [IICRC]. Obviously, she never sleeps.

*Accomplished Claudia’s appellation legend:

SSI – Substrates and Subfloor Inspector

CTC – Ceramic Tile Consultant

RFI – Resilient Floor Inspector

SCI – Senior Carpet Inspector

CWFI – Certified Wood Flooring Inspector

ASID – American Society of Interior Designers