contributed by The Folks at Fiber-Seal

contributed by The Folks at Fiber-Seal

Twelve years ago, we published a FIBERFAX article titled “Hidden Flame Retardants…Ticking Time Bombs.” We believed that the growing use of flame retardants in the home furnishings industry might turn into a significant problem. Our original assessment has proved to be accurate. The problems related to flame retardant ticking have cost consumers, designers, furniture manufacturers, cleaning companies and other related parties significant amounts of money paid out in damage claims over the last decade. A recent email to our technical department proves that this ticking problem is still occurring with alarming frequency and has not yet been solved.

The Problem

We were recently contacted by a test lab in North Carolina regarding strange color changes that had been cropping up on certain upholstered furnishings. Cushions on various pieces were changing color, even before the furniture was shipped. The cushions contained down (or a combination of foam and down) wrapped in a cotton ticking.

After further inquiry into the details of their problems – such as color changes in new furniture carefully wrapped in plastic for storage and as yet untouched – we assured the lab that they were experiencing what we have witnessed hundreds of times since the 1990’s: The Ticking Time Bomb.

After further inquiry into the details of their problems – such as color changes in new furniture carefully wrapped in plastic for storage and as yet untouched – we assured the lab that they were experiencing what we have witnessed hundreds of times since the 1990’s: The Ticking Time Bomb.

The Scenario

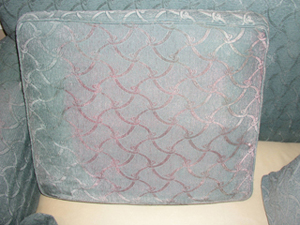

It starts as a very subtle color change that is barely noticeable. What’s most odd is that it looks like it’s happening only on the cushions. There is absolutely no sign of the problem on the arms of the furniture or any other areas.

Several weeks later it is obvious that the problem is getting worse. The color change, though still uneven, is starting to appear all over the cushions and is much more pronounced. Usually the discoloration worsens as more time passes.

Color change caused by flame retardant ticking follows a too- familiar pattern. Typical details include:

1 | Discoloration only on loose cushions. Face fabric is usually cotton.

2 | The presence of cotton ticking (inner fabric) with a pH of 5 or lower. Usually this type of ticking encases down filling material.

3 | Absence of discoloration at cushion seams where multiple layers of fabric inside the cushion and the “seam allowances” protect the face fabric from contact with the cotton ticking.

4 | Variance in pH on face fabric, with discolored areas being more acid than non-discolored areas.

Reducing Flammability

The State of California has a well-known flammability standard called Technical Bulletin 117 (TB117). This law outlines the standards for flame retardant treatment of resilient filling materials used in upholstered furniture. Section B-Part II of this standard states that feathers and down may be used in upholstered furniture only if they are encased in a “flame retardant fabric/ticking.” It then goes on to specify the flammability tests the ticking must pass.

Because manufacturers make most of their products to comply with TB117, California’s flammability rule serves as a de facto national standard. Flame retardant cotton tickings have thus become the industry standard.

Because manufacturers make most of their products to comply with TB117, California’s flammability rule serves as a de facto national standard. Flame retardant cotton tickings have thus become the industry standard.

pH-Induced Changes

The flame retardants being used to pass TB117 are applied to the interior of the cushion directly on the ticking. Unfortunately, these chemicals are very susceptible to leaching and eventually transfer to the face fabric in significant amounts.

The flame retardants in question are either acidic when first applied, or gradually degrade to acidic compounds as they age. On the vast majority of upholstery

fabrics, this shift in pH is not an issue. However, light-colored cottons tend to brown in acidic conditions. Also, certain fiber reactive dyes used on cotton fabrics tend to discolor very readily when exposed to acids.

What this means is that a sofa that is in perfect condition when it is first delivered can develop serious discoloration problems in as little as a few weeks.

What this means is that a sofa that is in perfect condition when it is first delivered can develop serious discoloration problems in as little as a few weeks.

Hope On The Horizon

The various segments of the furniture industry are now starting to come together to help solve this issue. Fiber-Seal Systems has offered our assistance because we are committed to helping find answers to this challenge.

We’re Here To Help

Got a question about a fabric or floor covering” We are happy to answer it for you. Trust Fiber-Seal to provide the latest information about elegant interior textiles and their care. This article first appeared in Fiber-Seal System’s FIBERFAX Volume Twenty-Two | Number One. Copyright © 2012 by Fiber-Seal Systems. All rights reserved.

Got a question about a fabric or floor covering” We are happy to answer it for you. Trust Fiber-Seal to provide the latest information about elegant interior textiles and their care. This article first appeared in Fiber-Seal System’s FIBERFAX Volume Twenty-Two | Number One. Copyright © 2012 by Fiber-Seal Systems. All rights reserved.